Some Known Incorrect Statements About Sheroz Earthworks

Some Known Incorrect Statements About Sheroz Earthworks

Blog Article

Rumored Buzz on Sheroz Earthworks

Table of ContentsSheroz Earthworks Can Be Fun For EveryoneRumored Buzz on Sheroz EarthworksEverything about Sheroz EarthworksThe Definitive Guide for Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.

For any earthwork specialist, it is vital to do job with high quality, accuracy, and on timetable. Using machine control in work equipments makes it possible for enhancing the various phases in the earthwork procedure, from intending to the maintenance phase - trimble parts. The equipment control system aids the equipment driver in attaining the target airplane quickly and easily

The machine control system guides the driver with centimeter accuracy. With Xsite PRO 3D, you'll constantly understand exactly just how much to cut or fill up. Your neighborhood Xsite technical assistance can guide you and aid with any troubles without visiting the website. Remote support saves money and time, as it reduces downtime in jobsites.

An Unbiased View of Sheroz Earthworks

Added training and guidelines are constantly available over remote support when needed. The earthmoving market has utilized our field-proven options since the early 1990s. Our system's components are carefully made to withstand the rough conditions of construction sites. Comparison of the very same task executed using machine control versus the traditional method reveals that, on average, the traditional approach requires 50% even more time to achieve the exact same task as the technology-assisted technique. https://pagespeed.web.dev/analysis/https-sheroz-com-au/hhalrkoyid?form_factor=mobile.

Sounds excellent? Enter the Xsite device control system; it's below to give you with a significant advantage when dealing with earthmoving equipment. Discover exactly how Xsite Machine Control can enhance your performance and make certain job security! We understand that learning a new innovation may really feel like a drag, yet do not worry! Our friendly and professional local support services have actually obtained you covered, ensuring that you can maintain functioning smarter without interruptions while on duty! Through remote support, your local Xsite dealer can provide assistance or troubleshooting without having to go to the site! What type of excavators does maker control fit? Xsite Maker Control systems can be set up to any type of excavator from mini excavators to huge mining excavators.

Exactly how does device control job? In 2D systems, the device is outfitted with calibrated disposition sensors.

The system is really simple to learn the fundamentals can be taught in under one hour of training. With Xsite you don't have to bother with finding out all the pointers and trick simultaneously. Extra training and guidelines are constantly offered over remote assistance when needed. Get in touch with your neighborhood Xsite dealer to discover even more! How does the remote assistance work? A cordless net link makes it possible to establish a remote connection between the maker control system and the solution.

Sheroz Earthworks - Questions

What kind of data styles Xsite systems assistance? Xsite Equipment Control systems sustain open common documents layouts, enabling seamless details circulation from one system to an additional. Sustained documents layouts: 2D-Maps: DXF Factor documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Versions: DXF, XML What parts are mounted on my machine? Depending on your choice of system (with or without positioning, i.e - trimble parts., 2D or 3D), your maker is furnished with inclination sensors, a controller device, and a display/operating panel.

Lots of hardware and software application services exist to aid establish an equipment's existing setting on the earth and compare it with a wanted design surfaceand building drivers can do even more to take advantage of the benefits. Equipment control is using various placing sensors and a screen to provide the driver with a recommendation between the placement of the bucket or blade and the target quality.

Depending on the arrangement, maker control systems can provide the driver with an easy aesthetic guide to pail or blade placement, or can immediately move the blade to grade by chatting to the device's hydraulics - https://www.kickstarter.com/profile/sherozau/about. There are maker control systems find out available for nearly any kind of device: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, milling devices, and pavers

Excitement About Sheroz Earthworks

Maker control can likewise assist boost efficiency and reduce general costs. Construction devices without equipment control will certainly come to be a thing of the past and the benefits gained from it will certainly be countless.

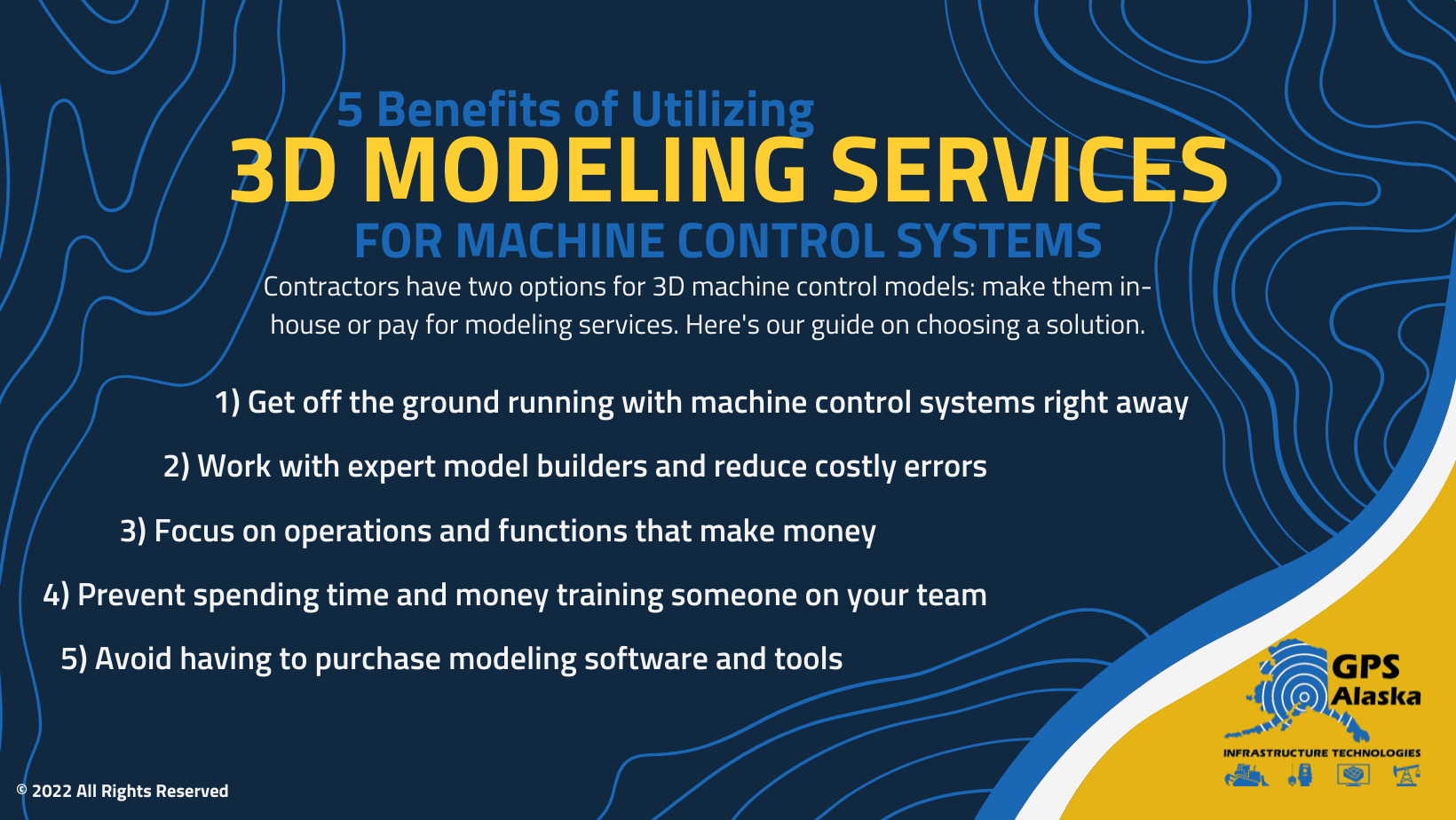

Trimble device control systems provide a myriad of advantages to anybody who uses earthwork equipment and, at EarthCalc, we can give you with 3D files for your machine control-enable tools. Not exactly sure if maker control is worth the expense? Think about the complying with reasons that you need to consider this choice.

Utilizing general practitioner aligned with your 3D design files, these systems practically assure that you will certainly eliminate or place the correct quantity of product at the building website. On many building and construction websites, rework is an usual and aggravating fact, yet with Trimble equipment control, you can remove the demand for rework.

Not known Facts About Sheroz Earthworks

Commonly, with Trimble machine control, you can eliminate excess devices at a details task site. A work that may have required the use of three or 4 pieces of digging deep into devices now might require only two pieces of devices to complete the same task in less time. This allows you to move your devices to one more work website and handle multiple tasks at one time.

Report this page